Data Center & Electronics Manufacturing

Specialized HVAC Solutions for Data Centers & Electronics Manufacturing—

Engineered for data centers and electronics

Industry Issues ——

Industry Problem Analysis

High Heat Load & Cooling Challenges

● Rack power density in data centers is increasing, often exceeding 10kW per rack.

● Electronics manufacturing equipment generates significant waste heat, difficult to handle with traditional cooling methods.

Energy Consumption & Cost Pressure

● Cooling accounts for over 40% of total data center energy usage.

● Manufacturing HVAC systems run continuously, leading to high electricity bills and maintenance costs.

Insufficient Precision in Temperature & Humidity Control

● Data centers require tight control: ±1°C temperature range and 40–60% humidity.

● Electronics production is humidity-sensitive: high humidity risks oxidation, while low humidity increases static discharge risks.

Reliability & Redundancy Requirements

● Any cooling system failure can cause downtime or production loss.

● Industry demands N+1 or 2N redundancy, but these often increase capital and energy costs.

Sustainability & Regulatory Pressure

● Both industries face carbon neutrality goals and stricter emission targets.

● Regulations are tightening on refrigerants and energy efficiency standards worldwide.

Key HVAC Requirements for Data Centers & Electronics Manufacturing——

HVAC Essentials for Sensitive Environments

Air Filtration & Cleanliness

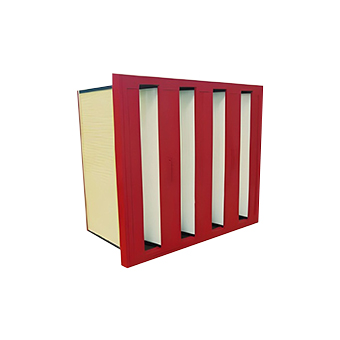

High-efficiency filters (HEPA / ULPA, MERV13 or above) to remove particles and pathogens; positive/negative pressure control in clean zones to prevent cross-contamination.

Airflow Management & Pressure Zoning

Use hot aisle/cold aisle containment, positive pressure in clean zones, and negative pressure in exhaust areas. High air-change rates ensure heat and contaminants are diluted quickly.

Temperature & Humidity Control

Maintain stable conditions (e.g., 18–27°C and 40–60% RH, per ASHRAE guidelines). Proper dew point and rate-of-change control help prevent condensation and electrostatic issues.

Redundancy & Reliability

24/7 continuous operation requires backup chillers, fans, UPS power, and dual-path or N+1 configurations for mission-critical equipment.

Energy Efficiency & Sustainability

Apply free cooling, liquid cooling, and heat recovery technologies. Intelligent control and optimization strategies help reduce overall power usage effectiveness (PUE).

Monitoring & Maintenance

Online monitoring for temperature, humidity, air quality, and pressure differential, combined with regular filter replacement, system calibration, and cleanroom validation.

Why Choose Aurashu as Your Trusted HVAC Partner

Expertise & Tailored Solutions

Aurashu has extensive experience in mission-critical environments, including data centers and electronics manufacturing facilities. We design customized HVAC and cleanroom systems that meet international standards (ASHRAE, ISO, GMP) and address the unique requirements of each project—whether it’s high-density server cooling or cleanroom particle control.

Reliability & Energy Efficiency

Our solutions are engineered for 24/7 uninterrupted operation, with N+1/2N redundancy, backup systems, and precision control. At the same time, we emphasize sustainability by integrating advanced energy-saving technologies such as free cooling, liquid cooling, heat recovery, and smart BMS control to reduce PUE and operating costs.

End-to-End Service & Global Support

From consulting, design, and equipment supply to commissioning and after-sales maintenance, Aurashu delivers complete lifecycle support. With a strong presence in the Asia-Pacific and global markets, our local teams provide responsive service and ensure seamless project execution worldwide.

Comprehensive HVAC Solutions for Data Centers & Electronics——

Aurashu Mission-Critical HVAC Solutions

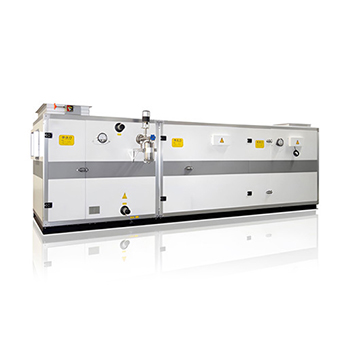

Custom HVAC & Precision Cooling

Tailored systems for data centers and electronics manufacturing, including chillers, CRAC units, and precision cooling equipment.

Cleanroom & Airflow Control

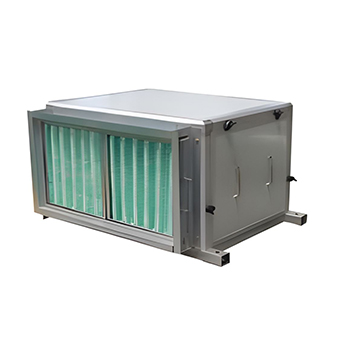

ISO-compliant cleanroom designs with advanced filtration, airflow containment, pressure zoning, and optimized ductwork for contamination prevention and efficient air distribution.

Redundancy & Reliability

Backup chillers, dual-path air distribution, and UPS integration ensure uninterrupted operation for mission-critical environments.

Energy Optimization & Sustainability

Advanced technologies such as free cooling, liquid cooling, and intelligent control systems reduce PUE and operating costs.

Monitoring & Maintenance

Real-time monitoring, cleanroom validation, and preventive maintenance programs ensure consistent system performance and compliance.

Products Used ——

Products and Core Equipment

Precision Cooling & Climate Control Systems

- Chillers (Air-cooled / Water-cooled) – Central cooling source for large data centers and fabs

- CRAC / CRAH Units (Computer Room Air Conditioning / Handling) – Precision air conditioning for server rooms

- Fan Coil Units (FCU) – Comfort cooling for staff and support areas

Air Treatment & Cleanroom Solutions

- Air Handling Units (AHU) – With multi-stage filtration, temperature and humidity control

- HEPA / ULPA Filtration Units – Ultra-clean air for semiconductor and electronics assembly

- Humidity Control Systems – Dehumidifiers / humidifiers for precise environmental balance

Airflow & Pressure Management

- Cold Aisle / Hot Aisle Containment Systems – Efficient air distribution for server racks

- Variable Air Volume (VAV) Boxes – Flexible air delivery and zone management

- Exhaust & Return Air Systems – Safe removal of contaminated or heated air

Intelligent Control & Monitoring Systems

- HVAC Control & Monitoring Platforms – Real-time temperature, humidity, and air quality control

- Building Management System (BMS) Integration – Centralized system management and IoT compatibility

Smart Energy Optimization Modules – Load balancing, predictive maintenance, and analytics - Remote Monitoring Systems – 24/7 alarms and cloud-based dashboards

Customer Case ——

Jinan Semiconductor Components Laboratory

Project Location

Heping Road, Jinan City, Shandong ProvinceApplied Products

Modular air conditioning units, air showers, fan housings, axial flow fans, Shangxin fans, fire dampers, purification systemsProject Description

Jinan Semiconductor Components Laboratory is a research-based institution specializing in the R&D, production, and sale of semiconductor devices and related products. It is a designated national manufacturer of military semiconductor devices.

Customer Case ——

Lite-On Electronics (Tianjin) Co., Ltd.

Project Location

Fuyuan Road, Wuqing District, TianjinApplied Products

Axial flow fans, diagonal flow fans, fire dampers, smoke exhaust vents, double-layer louver ventsProject Description

Lite-On Electronics (Tianjin) Co., Ltd. was established on September 15, 1995. The company's business scope includes the production of optoelectronics, power supplies, transformers, diode displays, and other light-emitting diodes.

Contact Us

- Request A Quote

- One-Stop Solution

- Latest Product Catalogue

- Free Consultation

- Name

- *Phone

- *Title

- *Content