Industrial Manufacturing & Chemical

Industrial Manufacturing & Chemical——

Safe Air,

Steady Production

Industry Issues ——

Industry Problem Analysis

Strict Environmental Control

Precision manufacturing, food, pharma, and chemical processes demand stable temperature (±0.5 °C), humidity (±3%RH), and clean air (ISO 5–8). Fluctuations can impact product quality, yield, and compliance.

Heat, Humidity & Dust Loads

Large-scale equipment releases heat, steam, and dust. High humidity accelerates corrosion, dust buildup risks explosions, and poor control degrades raw materials.

Hazardous Gases & VOCs

Chemical processes generate corrosive vapors, VOCs, and harmful gases. Without proper ventilation and scrubbing, safety and compliance are compromised.

Energy Consumption Pressure

Factory HVAC and ventilation systems run long hours at high load, often accounting for 30–50% of total plant energy use, creating heavy cost pressure.

Reliability & Production Continuity

Unexpected HVAC failures in continuous production can cause major financial losses. Redundancy and stable operation are critical.

Professional Team ——

Our Advantages

Deep Industry Experience

Years of experience across chemical, pharmaceutical, and heavy manufacturing projects.

Explosion-proof & Corrosion-resistant Design

Products certified to Ex d IIB T4, with >20 years corrosion resistance.

High Reliability & Safety

Redundant system configurations and continuous monitoring.

End-to-End Support

From system design and manufacturing to commissioning, training, and after-sales.

Solution Implementation ——

Implementation Strategy

Constant Temperature & Humidity Control

Industrial-grade HVAC ensures ±0.5 °C temperature accuracy and ±3%RH humidity stability. Multi-stage filtration (pre + medium + HEPA) provides ISO 5–8 cleanroom air quality for sensitive processes.

Redundancy & Monitoring

N+1 redundancy ensures uptime. Central BMS/EMS continuously tracks temperature, humidity, pressure differentials, and gas concentrations, providing auto alarms and preventive maintenance.

High-heat & High-humidity Management

Refrigerated dehumidification with reheat control, evaporative cooling, and high-volume ventilation rapidly remove heat and moisture, protecting both products and equipment.

Energy Saving & Recovery

Heat recovery systems recycle process heat for winter heating and summer cooling. VAV and frequency control reduce energy use by 15–30%. High-efficiency exchangers and insulation further cut losses.

Hazardous Gas Ventilation & Safety

Explosion-proof fans, corrosion-resistant heat exchangers, and localized fume/dust extraction with activated carbon scrubbers ensure safe, compliant operations. Negative-pressure zoning prevents leakage into non-production areas.

Core System Solution Highlights ——

System Excellence at a Glance

Explosion-proof HVAC Units

Certified to Ex d IIB T4 explosion-proof standards, designed for hazardous environments such as chemical plants and steel mills. Ensure safe operation even in the presence of flammable gases or dust.

Industrial Dust Removal & Purification

Multi-stage filtration, electrostatic precipitators, and gas scrubbing modules effectively capture fine dust, VOCs, and corrosive gases. Maintain clean and safe working environments while protecting equipment.

Corrosion-resistant Composite Ducts

Engineered with advanced composite materials, offering 20+ years of durability against acid, alkali, and salt spray environments. Reduce long-term maintenance costs and extend system lifespan.

Central Monitoring & BMS Integration

Integrated with Building Management Systems (BMS) or Energy Management Systems (EMS) to provide real-time monitoring of temperature, humidity, pressure differentials, and gas concentrations. Enable predictive maintenance and enhance plant safety.

Noise & Comfort Optimization

Low-noise fans, acoustic enclosures, and vibration isolation reduce noise and vibration in chemical plants and heavy industry—improving worker safety and meeting noise compliance standards.

Energy-efficient Heat Recovery Systems

Utilize waste heat and cooling recovery to reduce overall HVAC energy consumption by 15–30%. Support sustainable production while lowering operational costs.

Products Used ——

Products and Core Equipment

Ducted Purification Fresh Air Unit

- Durable composite duct systems;

- HEPA filtration & fume hoods.

Combined Commercial Air Conditioning Unit

- Anti-corrosion AHUs & chillers;

- Precision industrial dehumidifiers.

Activated Carbon Air Filter

- VOC removal with carbon scrubbers;

- Industrial dust collectors;

- Local exhaust systems.

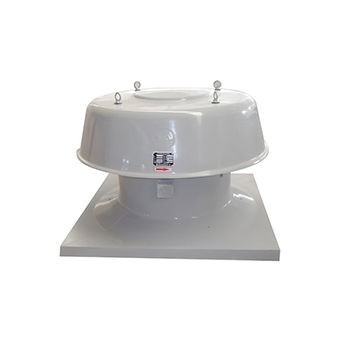

FRP Anti-corrosion Ventilation Equipment

- Long-lasting resistance against acid, alkali, and humidity;

- Efficiently exhausts hazardous gases in compliance with standards;

- Ideal for chemical plants, laboratories, and coastal industrial environments.

Customer Case ——

Shougang Group

Project Location

Beijing, ChinaApplied Products

Explosion-proof air handling units, large industrial ventilation fans, corrosion-resistant composite ducts, central monitoring and control systemsProject Description

As one of China’s largest steel enterprises, Shougang operates blast furnaces, rolling mills, and coking plants that generate extreme heat, dust, and corrosive gases. To address these harsh conditions, we provided a customized HVAC and air purification solution. The system features explosion-proof AHUs, high-temperature corrosion-resistant ducts, and large-capacity dust collection units, supported by a central BMS/EMS for real-time air quality and safety monitoring. With N+1 redundancy and energy-saving heat recovery, the system ensures uninterrupted operation, reduces energy use by 15–20%, and meets national safety and environmental standards.

Customer Case ——

Qingdao Brewery

Project Location

Qingdao, Shandong ProvinceApplied Products

Packaged AHUs, refrigerated dehumidification systems, HEPA filtration, rooftop ventilation unitsProject Description

Qingdao Brewery, one of China’s most iconic food & beverage brands, requires strict control over temperature, humidity, and air cleanliness during its brewing and packaging processes. Any fluctuation could impact product consistency and quality. We delivered an industrial-grade constant temperature and humidity control system, achieving ±0.5°C temperature precision and ±3%RH humidity control. A multi-stage HEPA filtration system ensures air purity in bottling areas, while refrigerated dehumidification prevents condensation and mold growth. The system not only safeguards production quality but also reduces HVAC energy consumption by 18%, supporting both food safety compliance and green manufacturing goals.

Contact Us

- Request A Quote

- One-Stop Solution

- Latest Product Catalogue

- Free Consultation

- Name

- *Phone

- *Title

- *Content