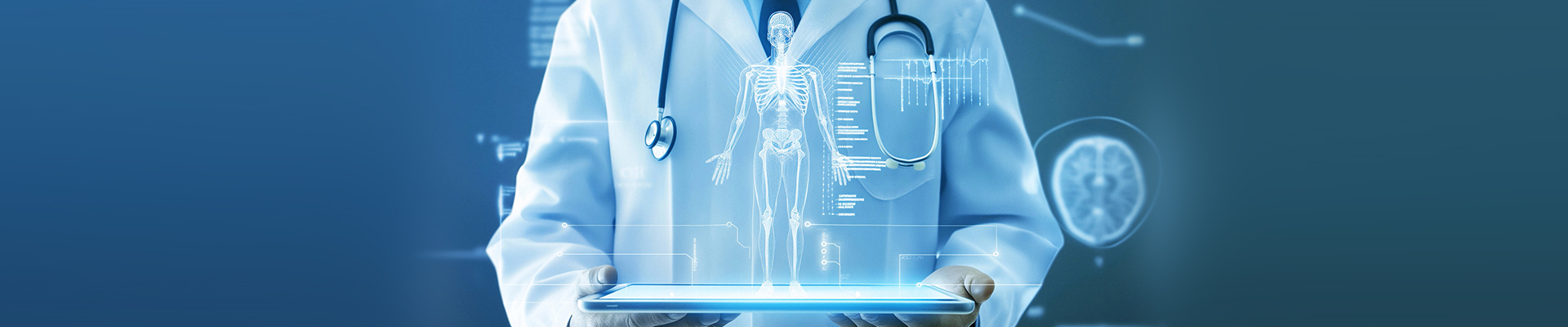

Healthcare

Why Healthcare Facilities Need Specialized HVAC Solutions—

Aurashu

Healthcare HVAC Solutions

Aurashu provides tailor-made HVAC solutions for hospitals, clinics, laboratories, and care facilities, designed to meet or exceed international healthcare standards.Contact Us

Industry Issues ——

Industry Problem Analysis

Strict environmental control requirements

Temperature, humidity, cleanliness, and airflow direction are directly related to the safety of diagnosis, treatment, and laboratory experiments.

Cross-infection risk

The risk of airborne pathogens spreading is high, especially in infectious disease departments and operating rooms.

High equipment stability requirements

Air conditioning failure can lead to surgical interruptions and sample waste.

Complex zoning requirements

Airflow and pressure requirements vary significantly between departments and laboratory areas.

Pressure to comply with standards

Different countries and regions have strict standards for medical air quality and cleanliness.

Medical institutions must continuously invest in equipment upgrades to meet these standards.

Key Requirements in Healthcare HVAC——

Core Demands of Healthcare HVAC

Air Filtration & Cleanliness

High-efficiency filters (HEPA / ULPA, MERV13 or above) to remove particles and pathogens; positive/negative pressure control in clean zones to prevent cross-contamination.

Ventilation & Air Changes

High air change rates (ACH) for critical areas such as operating rooms and diagnostic labs; balanced outdoor air supply, exhaust, and return systems.

Temperature & Humidity Control

Strict ranges (e.g., OR 18-23°C, 30-60% RH) to ensure patient safety, equipment stability, and prevention of bacteria/mold growth.

Pressure Zoning

Cleanroom zoning with positive pressure (OR/ICU) or negative pressure (isolation rooms) for infection control.

Reliability & Redundancy

Backup systems (dual units, standby fans/chillers) and reliable power supply to ensure continuous operation during emergencies.

Monitoring & Maintenance

Regular filter replacement, cleaning, and continuous monitoring of pressure, temperature, humidity, and air quality.

Professional Team ——

Our Advantages

Deep Industry Experience

Extensive experience in Asia-Pacific healthcare projects with compliance to local and international codes

Innovation & Customization

Comprehensive customization, sample validation, and design confirmation process

High Quality & Reliability

Certified products ensuring stable, long-term performance.Strong after-sales support and long-term maintenance services

Comprehensive Technical Support

Expert engineering team with backgrounds in hospitals, clinics, labs, and eldercare facilities

Specialized HVAC Solutions for Healthcare Environments ——

Aurashu HVAC Solutions for Healthcare Facilities

Customized Ventilation & Filtration Systems

● HEPA / ULPA filtration and modular fresh air units designed for wards, operating rooms, and isolation areas

● Controlled airflow patterns with pressure differential management

Temperature, Humidity & Pressure Control

● Precision temperature and humidity systems with adjustable ranges

● Positive/negative pressure zoning for infection prevention

Redundant & High-Reliability Systems

● Dual system backup, emergency power integration

● Durable components ensuring 24/7 stable operation

Smart Monitoring & Infection Control Integration

● Real-time monitoring of IAQ, pressure, and humidity

● Integration of disinfection technologies (UV, photocatalysis, ionization)

Energy Efficiency & Sustainability

● High-efficiency chillers, VFD fans/pumps, and energy recovery systems

● Optimized system design to reduce long-term operating costs

Products Used ——

Products and Core Equipment

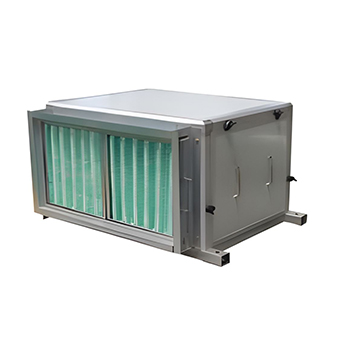

Air Treatment & Filtration Systems

- Air Handling Units (AHU) – Equipped with multi-stage filtration (pre-filter, medium, HEPA/ULPA) to ensure sterile and clean air delivery for operating rooms and ICUs.

- HEPA Filtration Units – Ceiling-mounted or standalone modules that provide ultra-clean air in sensitive areas like isolation wards and laboratories.

- Fresh Air Ventilation Systems – Supply 100% fresh air with energy recovery, maintaining proper oxygen levels and preventing cross-contamination.

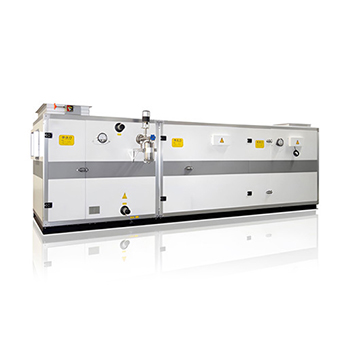

Cooling & Climate Control

- Chillers (Air-cooled / Water-cooled) – Central cooling sources designed for hospitals and large medical facilities, delivering energy efficiency and stable performance.

- Precision Air Conditioning Units – High-accuracy temperature and humidity control for laboratories, pharmaceutical storage, and equipment rooms.

- Fan Coil Units (FCU) – Compact indoor cooling/heating terminals for patient wards, clinics, and staff areas, ensuring comfort and quiet operation.

Pressure & Airflow Management

- Negative / Positive Pressure Units – Maintain correct air pressure differentials for isolation rooms, operating theaters, and ICUs to control infection spread.

- Variable Air Volume (VAV) Boxes – Flexible airflow adjustment for different zones, ensuring both comfort and energy savings.

- Exhaust & Return Air Systems – Specialized exhaust with disinfection options (UV, filtration) to safely remove contaminated air.

Intelligent Control & Monitoring

- HVAC Control & Monitoring Systems – Integrated solutions with sensors for temperature, humidity, differential pressure, and air quality.

- Building Management System (BMS) Integration – Enables centralized monitoring, real-time alerts, and IoT-based remote management.

- Smart Infection Control Modules – Optional features like UV sterilization, ionization, or photocatalytic purification for added hygiene.

Customer Case ——

Beijing Xiaotangshan Hospital Renovation Project

Project Location

BeijingApplied Products

Fire dampers, ceiling-mounted air conditioner units, packaged air conditioner units, centrifugal fans, DEF (DT)Project Description

Beijing Xiaotangshan Hospital, originally built as a SARS emergency facility in 2003, was renovated in early 2020 when COVID-19 broke out. The project aimed to upgrade its infectious disease prevention and treatment capacity.

Customer Case ——

Beijing Children's Hospital Baoding Branch

Project Location

3399 Hengyuan North Street, Baoding CityApplied Products

Air-cooled, Heat pump units, Clean air units, and box-type exhaust hoodsProject Description

Our company was responsible for all aspects of this project, including air conditioning and ventilation, fresh air purification, negative pressure, interior design, electrical, and plumbing services for the first-floor fever clinic, second-floor PCR lab and laboratory, and fourth-floor infectious disease ward. The project quality standard was a one-time acceptance inspection. Since its commissioning, the units have been operating smoothly, and all indicators have met the hospital's requirements.

Contact Us

- Request A Quote

- One-Stop Solution

- Latest Product Catalogue

- Free Consultation

- Name

- *Phone

- *Title

- *Content