Biopharmaceuticals

Biopharmaceuticals ——

Pure Air,

Assured Quality

Industry Issues ——

Industry Problem Analysis

Strict Environmental Requirements

Drug production requires ISO Class 5–7 clean environments, with constant temperature (±0.5°C) and humidity (±3%). Fluctuations can directly impact drug quality and yield.

Cross-Contamination Risks

Without proper airflow zoning and control, dust, microorganisms, or vapors can easily cause cross-contamination between clean areas.

Regulatory & Certification Pressure

Compliance with GMP, FDA, and ISO standards demands strict system design, validation (IQ/OQ/PQ), and traceable monitoring records.

Stability & Reliability

Continuous operation is critical—any HVAC failure can cause production interruptions and large-scale product losses.

High Energy Consumption

Cleanroom HVAC and constant temperature-humidity systems are energy-intensive, requiring advanced energy-saving strategies.

Professional Team ——

Our Advantages

Deep Industry Experience

Decades of HVAC and cleanroom project experience tailored to pharmaceutical standards.

Compliance & Validation

Support for GMP/FDA certification, including design, documentation, and system validation.

High Quality & Reliability

Redundant system configurations ensure continuous operation.

Comprehensive Technical Support

From design, installation, validation, to environmental monitoring and after-sales support.

Solution Implementation ——

Implementation Strategy

Independent Zone Control & Rapid Adjustment

Different cleanrooms (e.g., ISO 5, ISO 7, ISO 8) are equipped with independent constant temperature and humidity systems, enabling fast response to process load changes.

Low-Noise & Cleanroom-Compatible Design

Cleanroom-grade fans and air ducts with vibration isolation minimize noise and particles, keeping sound levels low while maintaining GMP compliance.

Specialized Solutions for Production & Labs

Sterile manufacturing areas use laminar flow systems with unidirectional air; laboratories and weighing rooms adopt negative pressure design to prevent contamination spread.

Energy Saving & Smart Operation

Variable air volume (VAV) and inverter technology adjust cooling/heating load by demand; waste heat recovery reduces HVAC energy use by 20–30%.

Air Health & Fresh Air System

Fresh air units with multi-stage HEPA filtration, UV disinfection, and pressure zoning maintain sterile air quality and prevent cross-contamination.

Core System Solution Highlights ——

System Excellence at a Glance

Precise Cooling & Heating Systems

Industrial-grade constant temperature and humidity units (±0.5°C / ±3%RH), with fast response to load changes and redundancy design for critical production stability.

Clean Air Handling & Ventilation

Multi-stage filtration (pre + medium + HEPA/ULPA), laminar flow, and pressure zoning with CO₂/VOC monitoring to ensure ISO Class 5–7 cleanliness and air safety.

Contamination Control Systems

Airlocks, pass-through windows, “clean-to-dirty” airflow, and local exhaust ensure strict separation between zones and reduce cross-contamination risks.

Control & Automation

Integrated BMS/EMS with environmental monitoring, real-time alarms, and traceable data (IQ/OQ/PQ) to meet GMP/FDA validation requirements.

Quiet & High-Precision Equipment

Low-vibration, low-noise fans and FFU/HEPA units maintain stable airflow without disturbing sensitive pharmaceutical processes.

Energy Saving & Sustainability

Heat recovery, VFD/VAV, and intelligent energy management achieve 20%+ energy savings while ensuring compliance and cost control.

Products Used ——

Products and Core Equipment

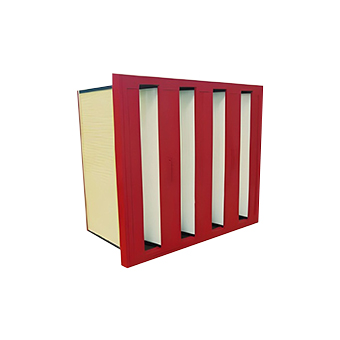

HEPA High Efficiency Air Filter

- ≥99.97% efficiency for 0.3µm particles;

- Ensures ISO Class 5–7 cleanroom compliance.

IAQ Fresh Air Unit

- Multi-stage filtration with fresh air supply for clean environments;

- CO₂/VOC monitoring with adaptive airflow control.

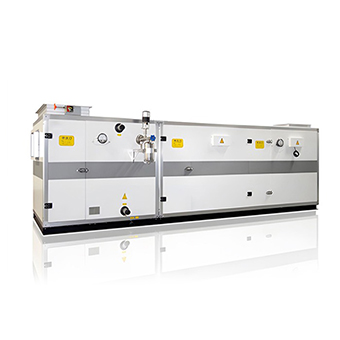

Constant Temperature & Humidity Units

- ±0.5 °C / ±3% RH precision control;

- Built-in dehumidification & reheat;

- GMP-compliant with redundancy.

Purification Air Handling Unit

- Multi-stage filtration (HEPA included) for ISO clean levels;

- Laminar airflow to prevent contamination;

- Integrated temp–humidity control for stable conditions.

Customer Case ——

Huaguoshan Medical Science Center, China Pharma Port

Project Location

Lianyungang, Jiangsu ProvinceApplied Products

Constant temperature & humidity cleanroom units, purification air handling units, HEPA filters, cooling towers, ducts, and intelligent control systems.Project Description

Located in the China Pharma Port of Lianyungang, Jiangsu Province, the Huaguoshan Medical Science Center is a key biopharmaceutical R&D and production hub. The facility integrates drug discovery, pilot testing, and large-scale manufacturing. The project adopted GMP-compliant HVAC and cleanroom purification systems, achieving ISO Class 5–7 controlled environments with precise temperature and humidity regulation, supporting cutting-edge biomedical research and industrial application.

Customer Case ——

Suzhou Industrial Park Biomedicine Innovation Center

Project Location

Suzhou, Jiangsu ProvinceApplied Products

Constant temperature & humidity units, HEPA filtration systems, IAQ fresh air units, purification AHUs, and BMS intelligent control platforms.Project Description

The Biomedicine Innovation Center in Suzhou Industrial Park is a leading hub for biopharmaceutical R&D and pilot-scale production. The facility required advanced clean HVAC and environmental control systems to meet stringent GMP and ISO cleanroom standards. Our solution delivered stable temperature and humidity control, high-efficiency filtration, and intelligent system integration, ensuring contamination prevention and reliable environmental stability for research and clinical trial production.

Contact Us

- Request A Quote

- One-Stop Solution

- Latest Product Catalogue

- Free Consultation

- Name

- *Phone

- *Title

- *Content