Services for Industrial & Manufacturing Clients

Industrial & Manufacturing Clients——

Full-Cycle Service Description

Core Services ——

One-Stop High-Reliability HVAC & Cleanroom Engineering

Process Consulting & Requirements Capture

Mapping process-critical parameters, analyzing loads and contamination sources, simulating airflow, and recommending centralized, zoned, or localized system architectures.

Precision Environment & Cleanroom Solutions

Tailored HVAC for precise temperature/humidity control, cleanroom and clean-zone design, and compliance with ISO/FS standards, including dust, ESD, and exhaust strategies.

Special Materials & Protective Design

Use of corrosion-resistant, chemical-resistant, antistatic, antibacterial, and temperature-resistant materials, with stainless steel or composite options for key components.

Redundancy & High-Availability Design

N+1/N+2 redundancy for cooling, dual power feeds with automatic transfer, backup pumps/fans, and failover logic to ensure uninterrupted production.

Smart Control, Monitoring & Analytics

PLC-based control integrated with BMS/SCADA for remote monitoring, alarms, historical logging, and automated optimization, offering dashboards and compliance reports.

Manufacturing, FAT & Batch Consistency

Custom-built units per specifications with full factory acceptance tests, batch consistency checks, and traceable inspection records.

Site Installation, Commissioning & Process Integration

On-site supervision, commissioning, and integration with production systems to meet performance criteria, with fine-tuned control logic and trial-run reporting.

Maintenance, Spares & Rapid Response (O&M)

Comprehensive O&M manuals, preventive maintenance, spare kits, 24/7 service options, and local spare parts stocking for rapid response.

Compliance Testing & Traceable Records

Third-party testing for IAQ, particle counts, chemical residues, with long-term log storage to support audits and certifications.

Sample List ——

Key Deliverables

- Process requirement specs, load calculations, airflow analysis

- System design and cleanliness documentation (with BOM)

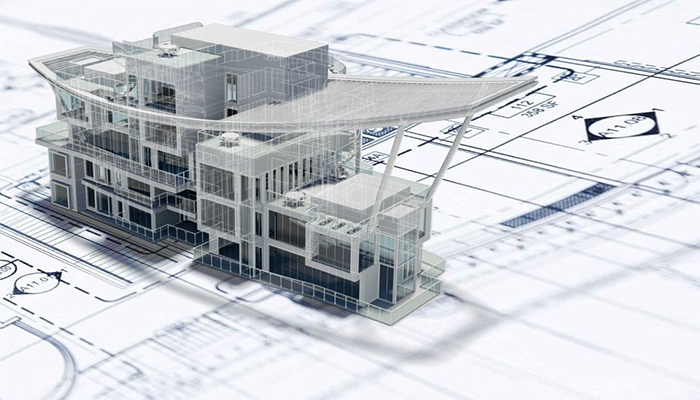

- BIM/IFC models and detailed design drawings

- FAT reports, batch consistency records, factory certificates

- Installation/commissioning/acceptance reports and performance data

- O&M manual, spare parts list, training records

- Third-party test certificates and energy reports

Ensuring Excellence ——

Quality Assurance & Project Control

Single Point of Contact (SPOC)

A dedicated project manager and site engineer provide unified and streamlined coordination throughout the project.

Milestone Acceptance

Clear written sign-offs at each stage—design, prototype, production, delivery, installation, and final acceptance.

Testing & Traceability

Factory acceptance tests (FAT), third-party validation, and batch traceability ensure consistent performance and compliance.

Spare Parts & Rapid Response

Regional spare inventories and flexible SLA options minimize downtime and ensure business continuity.

From Design to Delivery ——

Typical Timeline

| Project Name | Reference Period |

|---|---|

| Design & energy simulation | 2–4 weeks |

| Prototype fabrication & FAT | 4–8 weeks |

| Mass production | 6–12 weeks (dependent on scale) |

| On-site installation & commissioning | 2–8 weeks (dependent on scope) |

Value We Bring to Developers ——

How We Add Value

Cost Optimization

Smart controls and energy-efficient solutions reduce long-term operating expenses.

Yield & Consistency

Precision environmental control improves product yield and process consistency.

Production Continuity

Redundancy design and rapid response services ensure uninterrupted production.

Compliance & Audit Readiness

Traceable records and third-party testing support regulatory compliance and audits.

Maintenance Efficiency

Tailored spare kits and local service support minimize maintenance overhead.

Need Help?

- Request A Quote

- One-Stop Solution

- Latest Product Catalogue

- Free Consultation

- Name

- *Phone

- *Title

- *Content